Many tall buildings in cities are glass curtain walls, which are good outdoor advertising carriers. By means of

LED transparent screen technology, the building has become a three-dimensional photoelectric advertising carrier, which has become popular at home and abroad in recent years.

In the design of glass curtain wall LED display screen, the display content, space conditions, screen size, pixels and other important factors should be considered. At the same time, we must ensure that the production process and technical indicators meet the practical needs of glass curtain wall. Reasonable design should be combined with project cost.

I Point spacing

The point spacing is the distance between two adjacent LED lamp center centers, and the unit is mm. Visual particle sensation is mainly due to the human eye's resolution. When you watch two points at a distance, if two points reach a certain level, the human eye will be unable to distinguish. Over the past two years, with the improvement of LED display screen manufacturing technology, the resolution of LED screen of glass curtain wall has been continuously improved. Glass curtain wall display design has been upgraded from the minimum point distance specification scheme initially selected to the appropriate point distance specification scheme.

So, how do we choose the appropriate point spacing specification?

1.The point spacing is an important basis for the LED curtain wall type, and also determines the final display effect of the screen. The smaller the model, the smaller the distance between points. The higher the pixel density, the more suitable for high-definition content playback.

2.Point spacing and permeability are two difficult choices. The smaller the point spacing, the lower the permeation rate is. This is because the smaller the point spacing, the higher the pixel density. LED beads are more arranged in a unit area, which will inevitably lose part of the permeability, and high permeability is just the greatest advantage of LED display screen, and the price of improving the permeability is to expand the point spacing, which affects its picture clarity and display effect.

3.The viewing distance is an important basis for selecting the model. The farther the viewing distance is, the larger the screen area is, which is suitable for selecting large-scale products. The closer the viewing distance is, the smaller the screen area is, which is suitable for selecting small-scale products.

II Packaging technology

One factor that determines the quality of LED is the main material, such as box material, chip, lamp beads, power supply, etc. Another factor is the packaging process. The pixel packaging technology is related to the whole transparent screen color saturation, visual angle and other display effects, production costs, quality stability and so on. The transparent LED curtain wall packaging technology is mainly for the SMD mode. The SMD mode refers to pasting the encapsulated light-emitting tubes onto the circuit board and then welding the integrated circuit to form a screen. It has good heat dissipation and uniform color. The whole screen can be maintained frontally, which greatly reduces the maintenance cost and difficulty. At the same time, during the encapsulation process, metal compounds are added to make the mixing effect better and the light is softer.

III LED control part

The LED control part is the core part of the display effect. The control circuit has a high-performance single micro-control chip. The controller sends control signals and data to the LED drive chip through the internal control program. The LED driver chip receives the signal and generates the corresponding action, so it can control each red, green and blue LED chip separately.

3.1 Drive system

The function of the LED driver part is to receive color data and drive

LED display screen. According to the brightness value expressed by this data, there are three ways: constant current, steady voltage, constant voltage and constant current.

The output current of the constant current drive circuit is constant. The DC voltage of the output varies with the resistance of the load. The whole circuit is not afraid of load short circuit, but it is strictly forbidden to fully open the load. The voltage stabilizing circuit outputs a fixed voltage, and the output current varies with the increase or decrease of the load. The whole circuit is not afraid of opening the load, but it is strictly forbidden to short the load completely. First constant voltage and constant current mode is the most ideal driving circuit. It is not only necessary to detect the current of LED, but also to control the voltage of LED, which is conducive to improving the life of LED and reducing power consumption. It is generally used in high-grade LED products.

3.2 Control system

The display effect of LED depends on the magnitude and time of the current and voltage passing through it, so the control system is mainly to control the power output of LED. At present, the conversion efficiency of LED power supply designed by PWM (pulse modulation) control mode is as high as 80%-90%, and the output voltage or current is very stable, so it belongs to high reliability power supply.

PWM can control the ratio of LED opening and closing time. By dividing the time scale into several levels, the LED can display a corresponding number of gray levels (gray scale). The product of the gray level of the three primary color is the number of colors that can be reproduced theoretically. It is generally 256 levels, and the color number reaches 16.7M, which can display 24 bits of true color information.

IV Display demand

1. With unit modular planning, the whole screen has no seam. When you play the video, the image will not be cut by the joint, and then affect the visual viewing effect.

2. The color and brightness of the whole screen have consistency and uniformity, and can be proofread by point. This completely avoids the phenomenon of chromatic aberration, dark corner, dark edge and "patch".

3. Because of the great influence of outdoor light, the brightness requirement of LED curtain wall is above 4000cd/. It also supports intelligent conditioning of brightness. According to the surrounding environment, the picture is more comfortable and the details appear perfect.

4. It has a wide viewing angle and supports a large viewing angle of 140 degrees horizontally/vertically, which satisfies different viewing angles and covers more audiences.

V Installation mode

On the premise of avoiding destroying the appearance and structure of glass curtain wall, the installation method will be different according to the actual situation on the spot.

Full hidden frame: The LED transparent screen is fixed on the aluminum alloy frame. The upper and lower beams of the aluminum alloy frame are corresponding. The two sides of the glass correspond to the two vertical poles of the aluminum alloy frame.

Semi-invisible frame: Since both visibly vertical and invisible horizontal glass curtain wall and invisibly vertical and visible horizontal glass curtain wall are called semi-invisible frame glass curtain wall, this semi-invisible frame curtain wall glass has two installation modes. The visibly vertical and invisible horizontal glass curtain wall is to fix glass in the slot. The left and right sides are reinforced with glass glue. The invisibly vertical and visible horizontal glass curtain wall should be placed in the aluminum alloy inlay groove of the horizontal bar, and then cover the glass with pressure plate, and the aluminum alloy vertical bar is hidden behind the glass.

Open frame: For open frame curtain wall glass type structure, whether it is made of special aluminum alloy profile skeleton and glass frame or steel skeleton, the whole curtain wall aluminum alloy frame will be exposed outside.

Rack type: This is a kind of installation mode of column and stainless steel pendant welding. It connects the four claws of the pendant with the glass hole of the curtain wall, and one hole corresponds to one claw. It can also be said to drill a hole in each corner of the glass, and then fix the glass on the four claws of the stainless steel pendant.

Skeleton-free: Glass on a skeleton-free curtain wall can also be called structural glass. This kind of curtain wall is mostly used in the first floor of a building, similar to the floor windows of a building. The glass is installed in the form of hoisting. It is a method of hoisting the glass from above using a well-spaced hook or special profile. The operation step is firstly to fix the hook on the main frame of the channel steel, and then to suspend the channel steel under the plate or beam. To strengthen the stiffness of the glass, support frames or transverse gears can be installed on the top and bottom of the glass.

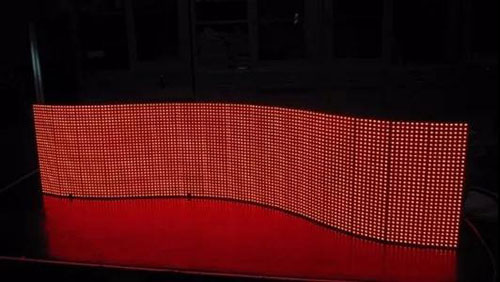

VI Shape structure

When building glass curtain wall structure is non-conventional plane modeling, such as arc, fan, triangle, circular and other structures, special design is needed to make LED curtain wall screen better adapt to the overall structure of the environment and use requirements.